Introduction

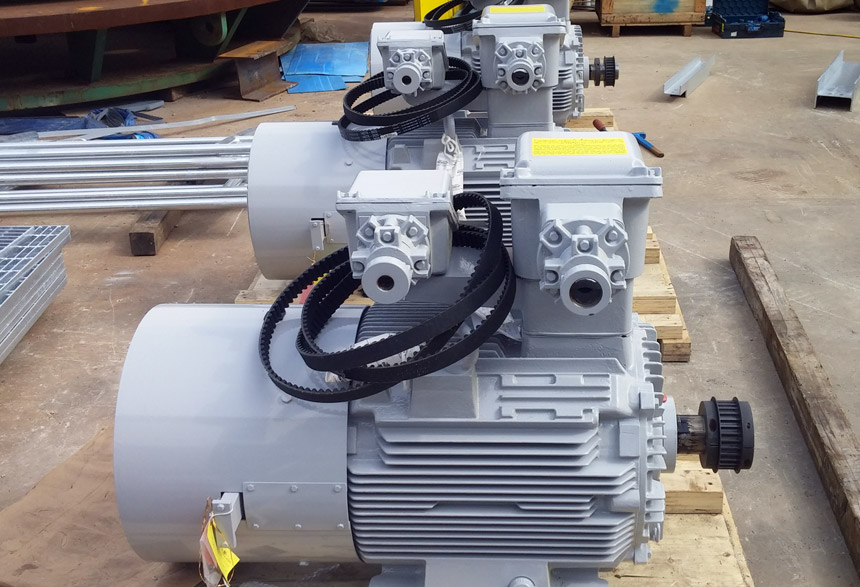

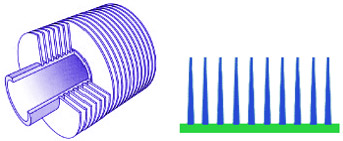

The fin fan cooler is a type of heat exchanger that utilizes air as the cooling medium. Its design incorporates finned tubes to expand the heat transfer surface, resulting in a more compact construction footprint. Unlike cooling towers that require a coolant, the fin fan cooler leverages natural air for cooling the process fluid. This not only reduces electricity consumption but also minimizes corrosion issues and lowers maintenance costs.

Key services associated with Fin Fan Coolers include:

- 3D Modeling Design: Advanced design techniques are used to create detailed 3D models of Fin Fan Coolers, ensuring precise construction

and optimal performance.

- Erection & Commissioning Supervision: Expert oversight during the installation and commissioning phases, guaranteeing that the cooler

is set up correctly and operates efficiently from the start.

- Maintenance Work: Comprehensive maintenance services to ensure the fin fan cooler continues to operate effectively, with minimal

downtime and extended service life.

Design Configurations :

i. Induced Type

ii. Forced Type

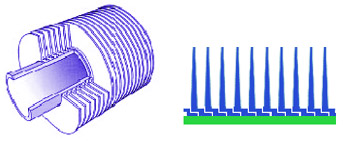

Fin Bonding Types

i. Embedded Fins - ”G”

Max.Temp. : 400 ℃(750 ℉)

ii. Extruded Fins - “Ext”

Max.Temp. : 300 ℃(570 ℉)

iii. Footed Fins - “L”

Max.Temp. : 130 ℃(270 ℉)

iv. Overlap Footed Fins – “LL”

Max.Temp. : 130 ℃(270 ℉)